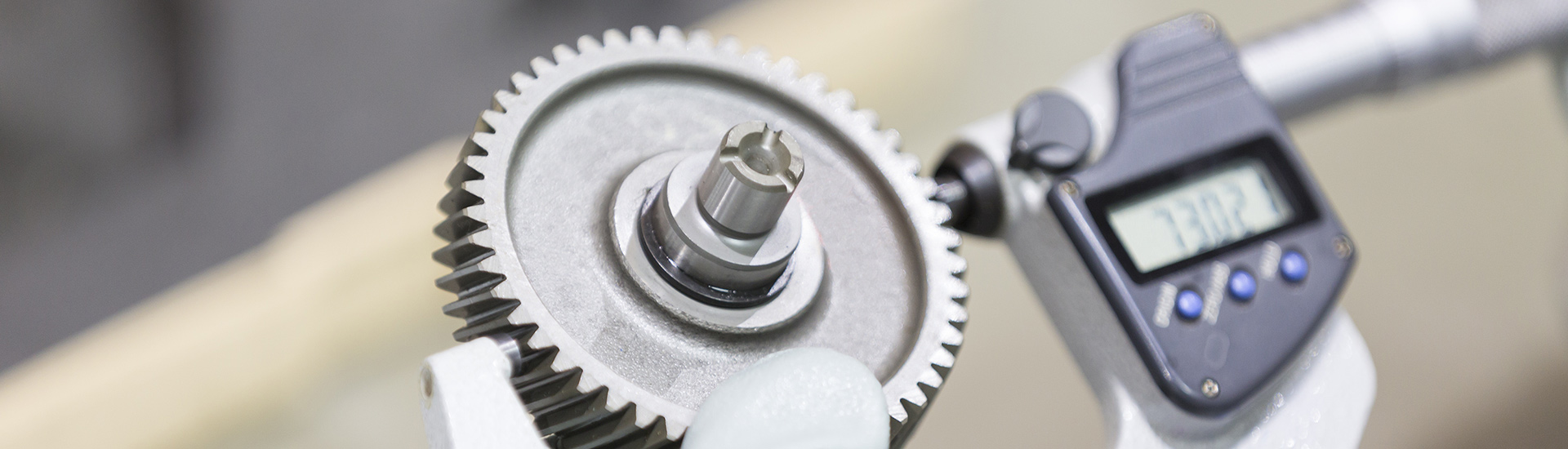

Cylindrical Gages

Using plug and ring gages is the one of the quickest ways to verify that products meet the print requirements. Commonly referred to a Limit Gaging or Functional Gaging, these tools are manufactured at the product limits. They have a Go member and a NoGo member. If the GO member is accepted by the part and the NoGo is rejected, then the part meets the print.

Ordering the tools, however, involves several decisions. There are a lot of variables for such a simple gage.

Select a class that is too tight, and the gage can wear out faster and must be replaced sooner, thus increasing inspection costs. Order a class that is too loose, and the gage may NoGo, or scrap potentially good parts.

The material selection affects gage life as well. Our experts can help you select the right tolerance and material for your application.

Class (Gage Tolerance): XXX, XX, X, Y, Z, ZZ

Material: Steel, Chrome, Carbide

Tolerance: + , -, Master, Go, NoGo